AC-700 P.E tape

Features

- · Long term corrosion protection and mechanical resistance

- · Outstanding electric property and permanent adhesion

- · Excellent weather & cold resistance

- · High chemical resistance under bad condition of soil Excellent working efficiency by hand or machine

- · Wide range of application and service temperature

- · Manufactured at ISO certified facility

- · Complies with AWWA C-209 & C-214 Standard

Sub-Materials

- AC-700 PRIMER

-

Anti-Corrosion Primer of synthetic resin & rubber blended with solvent, 20 liter per can or 200 liter per drum.

- 160g/m2 of Coverage.

- MASTIC FILLER

- Filler for uneven areas. 3.0mm 40mm 6.0m per roll

Simple Application

Remove rust, dirt, moisture, burr grease, knurl & all foreign matters completely by dry cloth, scrapping, wire brushing, disc grinding, sand or grit blasting. Stir Primer container well and apply it on the surface evenly by brush or roller. Allow curing for about 10min. Apply spirally SHAIC AC-700 P.E.Anti-Corrosion Tape and tension should be enough to obtain conformability to surface being applied. Minimum 25mm overlap, but 50% overlap(equal to two layers) recommended for optimum performance.

According to specification of the project, inner and outer tape can be applied. In case of welded joints, apply Primer on all surface to be wrapped and then Mastic Filler Tape along with weld beads and press firmly. Beginning at a point 25~50mm backward from end of left bare pipe, apply SHAIC AC-700 P.E.Anti-Corrosion Tape spirally to a point 25~50mm forward from end of right bare pipe.

Typical Physical Properties

| Properties | Unit | Values | Test Method | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 738 | 751 | 764 | 775 | 7100 | 7100B | ||||

| Total Thickness | mm | 0.38 | 0.51 | 0.64 | 0.75 | 1 | 1 | ASTM D1000 | |

| Backing Thickness | mm | 0.25 | 0.25 | 0.25 | 0.31 | 0.25 | 0.25 | ASTM D1000 | |

| Adhesive Thickness | mm | 0.13 | 0.26 | 0.39 | 0.44 | 0.75 | 0.75 | ASTM D1000 | |

| Tensile Strength | N/cm | 60 | 60 | 60 | 60 | 60 | 60 | ASTM D1000 | |

| Elongation | % | 550 | 550 | 550 | 550 | 550 | 550 | ASTM D1000 | |

| Adhesion Strength |

To P.E Lining | N/cm | 10 | 10 | 10 | 10 | 10 | 10 | ASTM D1000 |

| To Steel Pipe | N/cm | 20 | 23 | 27 | 28 | 30 | 30 | ASTM D1000 | |

| Dielectric Breakdown | KV | 27 | 27 | 27 | 27 | 27 | 27 | ASTM D149 | |

| Insulation Resistance | M · Ω | 107 | 107 | 107 | 107 | 107 | 107 | ASTM D257 | |

| Water vapor transmission | Perms | 0.13↓ | 0.13↓ | 0.13↓ | 0.13↓ | 0.13↓ | 0.13↓ | ASTM E96 | |

| Water Absorption | % | 0.05↓ | 0.05↓ | 0.05↓ | 0.05↓ | 0.05↓ | 0.05↓ | ASTM D570 | |

Application Table (Length of Tape Required)

| Pipe Size | Tape Width | SHAIC AC-700 Series | ||||

|---|---|---|---|---|---|---|

| 25% overlap | 50% overlap | Primer(160g/m2) | ||||

| DN | Inch | (mm) | (Inch) | (m) | (m) | (g) |

| 25 | 1 | 50 | 2 | - | 4.7 | 17 |

| 50 | 2 | 100 | 4 | 2.8 | 4.2 | 30.4 |

| 80 | 3 | 100 | 4 | 4.1 | 6.2 | 44.7 |

| 100 | 4 | 100 | 4 | 5.2 | 7.9 | 57.4 |

| 125 | 5 | 150 | 6 | 3.8 | 6.4 | 70.2 |

| 150 | 6 | 150 | 6 | 4.5 | 7.6 | 83 |

| 200 | 8 | 200 | 8 | 4.2 | 7.5 | 108.6 |

| 250 | 10 | 200 | 8 | 5.2 | 9.2 | 134.3 |

| 300 | 12 | 200 | 8 | 6.2 | 11 | 160 |

| 350 | 14 | 250 | 10 | 5.4 | 9.82 | 178.6 |

| 400 | 16 | 250 | 10 | 6.2 | 11.2 | 204.1 |

| 500 | 20 | 300 | 12 | 6.3 | 11.7 | 255.2 |

| 600 | 24 | 300 | 12 | 7.6 | 14 | 306.2 |

| 700 | 28 | 300 | 12 | 8.9 | 16.3 | 357.3 |

| 800 | 32 | 450 | 18 | 6.6 | 12.4 | 408.3 |

| 900 | 36 | 450 | 18 | 7.4 | 14 | 459.6 |

| 1000 | 40 | 450 | 18 | 8.2 | 15.5 | 510.4 |

| 1200 | 48 | 450 | 18 | 9.9 | 18.7 | 611.8 |

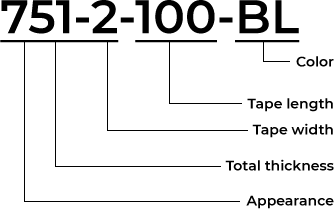

Ordering Information

- Standard Tape Type

- BL-Black, WH-White

- 50-100ft(15-30m)

- 2"~18"(50~450mm)

- 0.38~1.50mm(15~38mils)

- 700-tape

Product Selection

| Coating Thickness Required | Inner Wrap | Outer Wrap | Remarks |

|---|---|---|---|

| 2.0mm | 751-4-100-BL | 751-4-100-WH | 50% Overlap Recommanded |

| 2.5mm | 751-4-100-BL | 775-4-100-WH | |

| 3.0mm | 751-4-100-BL | 775-4-100-WH | |

| Joint Wrap | |||

| 2.0mm | 7100-4-50-BL | ||

| 3.0mm | 7150-4-33-BL | ||

Composition

Physical Characteristics

- · Dry Film Thickness: 55microns

- · Flash Point: -1~2℃

- · Temperature Range: -30~70℃

- · Coverage: Approx. 160g/m2

| Properties | Test Method | P23 | P27 | P30 |

|---|---|---|---|---|

| Solid Content | ASTM D2697 | 23% | 27% | 30% |

| Viscosity (23℃) | ASTM D1200 | 20±5sec | 22±5sec | 30±5sec |

| Specific Gravity (23℃) | - | 0.83 | 0.84 | 0.85 |

| Drying Time | ASTM D1640 | 5~10 minutes | 5~10 minutes | 7~15 minutes |

Features

- · Shake primer containers well and stir contents thoroughly

- · Primer can be easily and evenly applied by brush or roller

- · A careful caution must be paid not to creare air bubbling

- · Allow primer to dry for a minimum of 10 minutes

Storage Guidelines

- · To ensure maximum performance,

- · Store SHAIC products in a dry or ventilated area,

- · Keep products sealed in original cartons and

- · Avoid exposure to direct sunlight, rain, snow, dust or other sdverse environmental elements.

- · Avoid prolonged storage at temperature above 35°C(95°F) or below -20°C(-4°F)