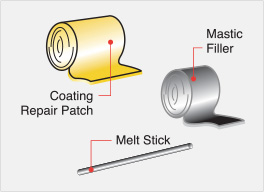

Repair Product

Product Repair Product

SHAIC pipeline coating repair products are widely used from the field in which is the pipe coaing damaged for a continuous stipendiary prevention effect. The Repair Patch, Mastic Filler and Melt Stick are the product. It will be able to repair the damage which occurs from pipe transportation and load process effectively.

Repair Patch

Repair Patch is composed of fiber inserted cross-linked polyolefin backing and heat sensitive adhesive.

This product has superior adhesion and sealing up effect as well. It will be able to expect reliable corrosion

prevention and shear forces and abrasionresistance. It can be used installed quick with no special tools

and skills required.

- · Size: 1.6mm X 150mm X 10m (up to 450mm width)

- · Code: RPR2-33-6-BL

Mastic Filler

Mastic Filler is used to fill larger voids and deep damaged coatings prior to the application of Repair Patch.

- · Size: 3.0mmx40mmx6m

- · Code : MF-100-4-BL

Melt Stick

Melt Stick is composed of heat-activated with a stick form. This product is used the place where the pipe surface it re- pairs a small damage. It could be used as a filler material with Repair Patch.

- · Size: 10mm diameter X270mm length

- · Supply: 3kg/box

roduct Selection Method

| Max. Operating Temperature | Compatible Line Coating Product |

Product | |

|---|---|---|---|

| Small damage or Scratch | 114°F(80°C) | PE, FBE, CTE | Only Melt Stick or With Repair Patches |

| Damage | PE, FBE, CTE | Melt Stick with Repair Patch or Mastic Filler with Repair Patch | |

| Large damage | Heat Shrinkable Sleeve is recommended. | ||

※ Note: Before ordering the product, for the selection of the product that is appropriate inquire surely in SHAIC representative.

Physical Properties

| Properties | Test Method | Values | |

|---|---|---|---|

| Inner Layer | Softening Point | ASTM E28 | 110℃ (217℉) |

| Lap Shear | DIN D1002 | 24N/cm2 (35psi) | |

| Outer Layer | Tensile Strength | ASTM D638 | 20Mpa↑(2840psi) |

| Elongation | ASTM D638 | 450%↑ | |

| Abrasion Resistance | ASTM D1044 | 38mg | |

| Hardness | ASTM D2240 | 45 | |

| Volume Resistivity | ASTM D257 | 1015Ω㎝↑ | |

| Dielectric Breakdown | ASTM D149 | 28kV | |

| Patch | Impact Resistance | ASTM E14 | Pass(Class C) |

| Peel Strength to Steel | ASTM 1000 | 25N/cm | |

| Water Absorption | ASTM D570 | 0.05%↓ | |

| Cathodic Disbondment | ASTM G8 | 12mm | |

Application Instruction

-

Pipeline Repair ProductsRepair Patch is typically shipped in bulk rolls and field cut to size. Melt Sticks and Mastic Fillers are used to repair holidays fill voids.

Pipeline Repair ProductsRepair Patch is typically shipped in bulk rolls and field cut to size. Melt Sticks and Mastic Fillers are used to repair holidays fill voids. -

Storage & Safety GuidelinesThese installation instruction are intended as a guide for standard products.

Storage & Safety GuidelinesThese installation instruction are intended as a guide for standard products. -

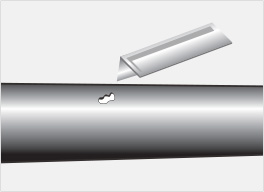

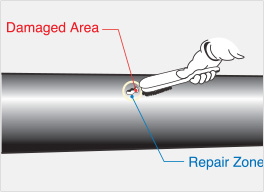

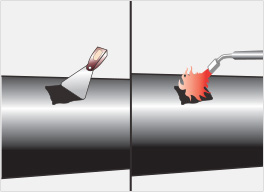

1. Removal of Damaged CoatingRemove damaged coating with a knife or hand grinder to prevent crack propaga tion in the coating.

1. Removal of Damaged CoatingRemove damaged coating with a knife or hand grinder to prevent crack propaga tion in the coating. -

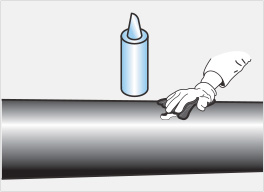

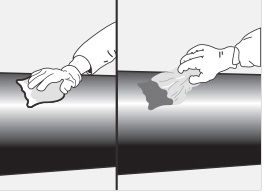

2. Solvent CleaningClean exposed steel and adjacent pipe coating with an approved cleaner (as per SSPC-SP-1) to remove the presence of oil, grease and other contaminants.

2. Solvent CleaningClean exposed steel and adjacent pipe coating with an approved cleaner (as per SSPC-SP-1) to remove the presence of oil, grease and other contaminants. -

3. Surface PreparationRemove adhering rust, coating chalk, dirt and roughen the mill applied coating in the repair zone using an abrasive paper! cloth or wire brush.

3. Surface PreparationRemove adhering rust, coating chalk, dirt and roughen the mill applied coating in the repair zone using an abrasive paper! cloth or wire brush. -

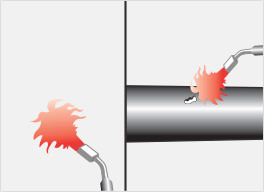

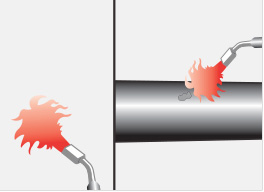

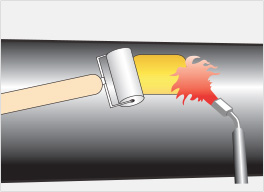

4-1. Melt Stick ApplicationUse a low intensity yellow flame for preheating the coating and applying the repair products. With quick back and forth stokes, pre-heat the repair zone suffi ciently to remove moisture and assist in adhesion.

4-1. Melt Stick ApplicationUse a low intensity yellow flame for preheating the coating and applying the repair products. With quick back and forth stokes, pre-heat the repair zone suffi ciently to remove moisture and assist in adhesion. -

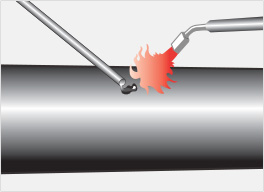

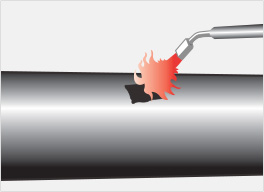

4-2. Melt Stick ApplicationHeat the Melt Stick and the repair zone simultaneously with the torch and spread the Melt Stick over the damaged area. Keep the flame moving to prevent dam- aged to the coating. Some ignition of the Melt Stick is acceptable.

4-2. Melt Stick ApplicationHeat the Melt Stick and the repair zone simultaneously with the torch and spread the Melt Stick over the damaged area. Keep the flame moving to prevent dam- aged to the coating. Some ignition of the Melt Stick is acceptable. -

4-3. Melt Stick ApplicationContinue spreading the Melt Stick over the repair zone until the entire area is covered. After sufficient melt stick material is on the surface, apply additional heat in quick back-and- forth strokes to create a smooth surface.

4-3. Melt Stick ApplicationContinue spreading the Melt Stick over the repair zone until the entire area is covered. After sufficient melt stick material is on the surface, apply additional heat in quick back-and- forth strokes to create a smooth surface. -

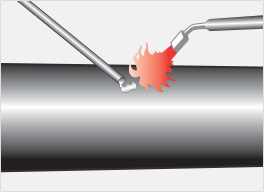

4-4. Melt Stick ApplicationEnsure that the Melt Stick material completely covers the repair zone. The Melt Stick material should be spread liberally so that the material is raised above the coating surface.

4-4. Melt Stick ApplicationEnsure that the Melt Stick material completely covers the repair zone. The Melt Stick material should be spread liberally so that the material is raised above the coating surface. -

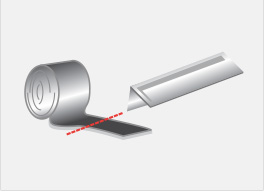

4-A. Mastic Filler InstallationFill deeper crevices with Mastic Filler (MF). Unroll the filler material and cut off the required amount.

4-A. Mastic Filler InstallationFill deeper crevices with Mastic Filler (MF). Unroll the filler material and cut off the required amount.

Leaving the release paper in place. -

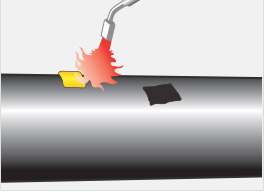

4-B. Mastic Filler InstallationUse a low intensity yellow flame for preheating the coating and applying the repair products. With quick back and forth strokes, pre-heat the repair zone sufficiently to remove moisture and assist in adhesion.

4-B. Mastic Filler InstallationUse a low intensity yellow flame for preheating the coating and applying the repair products. With quick back and forth strokes, pre-heat the repair zone sufficiently to remove moisture and assist in adhesion. -

4-C. Mastic Filler InstallationPlace the filler material onto the damaged area with the release paper facing up. Firmly press the material into the dam- aged area by hand and remove the re- lease paper.

4-C. Mastic Filler InstallationPlace the filler material onto the damaged area with the release paper facing up. Firmly press the material into the dam- aged area by hand and remove the re- lease paper. -

4-C. Mastic Filler InstallationAfter filling the damaged area, remove the excess filler to create a smooth sur face. As an option, use a low intensity yellow flame to warm the material and assist in smoothing it out.

4-C. Mastic Filler InstallationAfter filling the damaged area, remove the excess filler to create a smooth sur face. As an option, use a low intensity yellow flame to warm the material and assist in smoothing it out. -

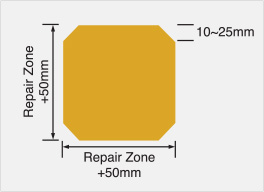

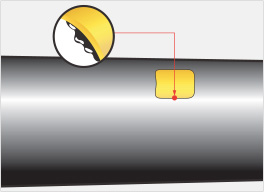

5. Patch PreparationCut a patch large enough to extend a mimimum of 50mm(2") beyond the edge of the repair zone. Trim each corner of the patch about 10- 25mm(1/2"-1") at a 45, angle.

5. Patch PreparationCut a patch large enough to extend a mimimum of 50mm(2") beyond the edge of the repair zone. Trim each corner of the patch about 10- 25mm(1/2"-1") at a 45, angle. -

6. Pre-HeatWarm the damaged area (repair zone + 50mm (2") overlap) to remove moisture and assist in adhesion.

6. Pre-HeatWarm the damaged area (repair zone + 50mm (2") overlap) to remove moisture and assist in adhesion. -

7. Patch InstallationAfter removing the release liner from the cut patch, place the patch with the adhe- sive side up on a gloved hand. Or on top of the pipe, and heat gently. Heat until the adhesive softens and the surface be- comes glossy. Also, reheat the damaged area to keep it warm.

7. Patch InstallationAfter removing the release liner from the cut patch, place the patch with the adhe- sive side up on a gloved hand. Or on top of the pipe, and heat gently. Heat until the adhesive softens and the surface be- comes glossy. Also, reheat the damaged area to keep it warm. -

8. Patch InstallationApply the softened adhesive side of the patch to the damaged area and press down firmly. Heat the patch with a low in- tensity flame, and usign a roller or a gloved hand, pat down and remove wrin- kles. Roll to ensure a good bond.

8. Patch InstallationApply the softened adhesive side of the patch to the damaged area and press down firmly. Heat the patch with a low in- tensity flame, and usign a roller or a gloved hand, pat down and remove wrin- kles. Roll to ensure a good bond. -

9. InspectionVisually inspect the installed patch for the following:

9. InspectionVisually inspect the installed patch for the following:1. Patch is in full contact with the pipe coating .

2. There are no loose edges.

3. A successful patch has adhesive flow on the edges.

4. The patch has fully conformed to the coating.

5. No cracks or holes in patch backing.